SSW - Epilog Fusion Pro 48 Laser Cutter

This document relates specifically to the Epilog Fusion Pro 48 but the general principles apply to the other laser cutters in the Maker Space.

Personal Protective Equipment

No specific PPE is required to use this equipment.

Specific risks you should be aware of

|

Fire Hazard Material may catch alight during engraving and cutting. |

|

Optical Radiation Do not look directly at the point where the laser is cutting. |

|

Laser Radiation You may be exposed to an invisible Class 2 Infrared laser if this machine is operated with interlocks defeated. This can cause immediate blindness and burns. |

|

Hazardous Fumes You must use the building's fume extraction to extract hazardous fumes and smoke. Combustion by-products may include carbon monoxide and hydrochloric acid. |

|

Approved Materials Only You are only permitted to cut approved materials. |

|

Crush Hazard Computer controlled machinery may move automatically. When the lid of the machine is open keep clear of moving parts. |

Turning on the equipment

- Turn on the centrally controlled laser cutter fume extraction system.

- Check the emergency stop button is not pressed by turning in the direction of the arrow.

- Close the lid of the laser cutter.

- Turn the key switch marked "Power" to the on position.

- Wait for the machine display screen to load fully and for the machine to finish its homing cycle before opening the lid.

Turning off the equipment

- Remove all material from the laser cutter. Snap spindly remnants and place on back on the shelf.

- Clean small remnants from the trays underneath the slat bed.

- Turn the key switch marked "Power" to the off position.

- If there are no other laser cutters in use you may turn off the fume extraction.

Fire during a laser cutting job

- You must stay with the laser cutter at all times while it is running, and monitor it for fire.

- Flames which travel with the laser cutter head are normal. In the event of flames in an area which is not currently being cut by the laser immediately press the emergency stop button on the top of the machine.

- Shout "Fire!" to alert otheres around you and gain attention of the Maker Space staff.

- Use your judgement to determine the severity of the fire.

- Small flames may be extinguished if it is safe to do so.

- In the event of a large fire do not open the lid of the laser cutter and exit the Maker Space via the nearest emergency exit.

- There should never be a large, out of control fire in the laser cutter because users are monitoring the laser at all times when it is running.

Tips for using this equipment

Always keep an eye on your cutting job

The laser cutter works by selectively burning your material. If your settings are incorrect, or the laser cutter software crashes, then there is a risk of fire. If this occurs, press the emergency stop button and inform a member of staff immediately. There is a CO2 fire extinguisher located next to the fire exit door by the laser cutters.

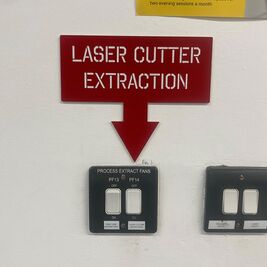

Turn on the fume extraction

You must use the fume extraction when laser cutting. Not using the extraction exposes all users of the Maker Space to hazardous combustion by products, fills the room with smoke, and will set off the fire alarm.

The fume extraction power switch is located on the wall opposite the door to the technician’s office.

Cover cut edges with masking tape

Cutting wood products like MDF and plywood can result in a sooty burn mark. Cover the areas you will be cutting through with masking tape on both sides before cutting. When you peel the tape off the sooty marks should be on the tape!

Use a vector mark to speed up detailed line engravings

If you have a lot of lines to grave you may find it quicker to use a very light vector cut instead of an engrave. Use a high speed (100%) and a low laser power (10-20% depending on material) to score the top surface of MDF and plywood without cutting all the way through.

Experiment with the laser settings

Try out the laser settings on an offcut or scrap before committing to a full sheet. Sometimes you can get away with less power or more speed. Keep a note of settings which work well for you!

Use material offcuts before cutting into a fresh sheet

Material is becoming more expensive – try to use offcuts wherever possible, even if it means splitting one job into several smaller jobs.

Nest your work efficiently

Make sure that you are making the most effective use of the material which is being provided. Excessive material wastage may result in the Maker Space charging for material in the future.