Starting a laser cutter job (Epilog Fusion Pro)

Safety

- Review the Safe System of Work document before starting work.

- You must stay with the laser cutter at all times when it is cutting or engraving. There is a high risk of fire, therefore the process must be monitored. If you need to leave the laser you must pause the job.

- You must turn on the fume extraction before you start cutting. The fumes produced by laser cutting are hazardous, and the smoke produced will set off the building's fire alarm.

- Check the approved materials list before cutting. Some materials are unsafe to cut because of hazardous fumes or combustion byproducts. You must never cut PVC.

Turn on the laser cutter

|

Use the key switch on the top of the machine to turn on the laser cutter. Ensure the emergency stop button hasn't been pressed by twisting it in the direction of the arrows. |

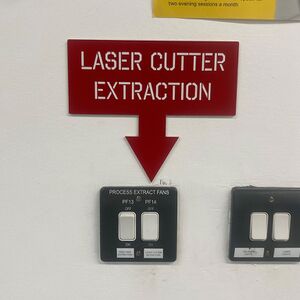

Turn on the fume extraction

|

On the wall opposite the Technician's Office there is a switch clearly labelled "Laser Cutter Extraction". It must be turned on at all times when the laser cutters are running. |

Focus the laser on your workpiece

The laser must be focused properly. Incorrect focusing will at the least cause poor accuracy and bad quality cuts. At worst it can cause a fire that will destroy the machine and endanger life.

- Place your material on the machine bed.

- Press the Joystick icon on the control panel.

- Use the actual joystick to move the head of the laser over your workpiece. There is a small plunger on the back left of the laser head which is used for setting the focus distance - make sure that this is clearly over the top of your material.

- Close the lid of the laser cutter.

- Press the Autofocus button on the control panel. Wait for the autofocus cycle to finish.

- Press the Park Axis button to move the head back to the home position.

Setup your job in Epilog Dashboard

Print your file from Illustrator and set it up in Dashboard. Print to the machine so your job is ready in the queue.

Checking your job will fit on the material

Use the cameras in the lid of the laser cutter to make the most of the material available.

Use offcuts wherever possible - don't cut into brand new sheets or large offcuts when there is a smaller offcut you can use instead.

You can also double check by using the outline trace feature on the laser cutter.

- Press the hamburger menu at the top right of the control panel display - it's a series of thick horizontal lines. This will display the list of jobs ready to be cut.

- Press on your job from the list to select it.

- At the bottom right of the control panel display there is the trace outline button - to the right of the joystick icon. Press this to start the laser tracing the rectangular extremes of your design. This should automatically turn on the red dot pointer, but if it doesn't you can turn it on with the icon in the middle of the bottom row.

Start your job

- Double check the laser cutter fume extraction is still running - you should be able to hear the airflow through the ducts.

- Make sure you have selected the correct job from the job list.

- Press the physical Play/Pause button at the bottom left of the control panel to start the job.

- Pressing the Play/Pause button again will pause the machine at the end of the current line segment it is cutting or engraving.

- Cancel the job by pausing the machine and pressing the Park Axis button.

- In the event of a fire (that is, flame that is not following the laser head around the material but burning independently) press the emergency stop and inform a member of technical staff immediately and with a sense of urgency.

During the job

You must stay with - and pay attention to - the laser cutter at all times when it is running. There is a high risk of fire and equipment damage if it is left running unattended. Pause the machine and wait for it to stop before leaving it.

Fill out the laser cutter log form - this helps us keep (relatively expensive) material free by showing where it is going.

After the job has finished

Remove your material and cut parts from the machine bed. Break off useless sections of material and put them in the bins next to the laser area, and place useful trimmed offcuts on the offcut shelf.

Remove remnant material from the slats, you can use the hoover to suck them out or