Material Nesting

| This placeholder article needs more information adding to it. More details are coming soon, if you can please ask the technical staff for a wiki account and help out. |

All sheet-based material processes like waterjet cutting, CNC routing, and laser cutting benefit from efficient material use through effective nesting.

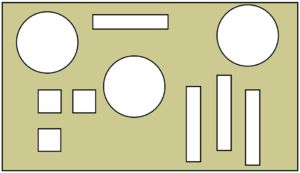

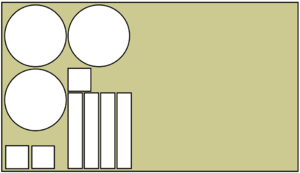

Basic Nesting

The most basic form of nesting is to use 2D CAD software like AutoCAD, Adobe Illustrator, or OMAX Layout to arrange your designs as close together as your cutting process allows. For laser cutting and waterjet cutting this is approximately 3mm apart, depending on the thickness of your material.

Clean-cutting offcuts

Where possible you should add extra lines to your cutting profile to cut material square. In the "acceptable nesting" example image it would be a good idea to add a single vertical cut to separate the useless offcut material on the left from the clean, unused material on the right.

This clean material can then either go back on the material rack (if it is of substantial size) or into the offcuts rack for the next person to use.

Cost of Materials

Financial cost

The Maker Space aims to provide free materials (where reasonable!) for staff and students at the University so there are no barriers to learning. Excessive material waste is not acceptable though - you should treat the material as if you had bought it with your own money. When parts and designs are cut in an inefficient manner (such as by cutting holes in the middle of fresh sheets of material) there is a substantial cost involved in buying new replacement material.

Environmental cost

All consumables have an non-negligible impact on the environment. Nesting your parts effectively and efficiently means that fewer raw materials are required to make stock for use.

A lot of the materials used, especially in CO2 laser cutting, are not directly recyclable and therefore enter the general waste stream. Some materials (such as plywood and MDF) may be redirected from landfill to be burned in incineration plants but others like acrylic and laminated signwriting plastic are difficult to recycle.

Use offcuts before cutting into a new sheet

Our main laser cutter - the Epilog Fusion Pro 48 - has a pair of cameras affixed to the lid. These allow you to use offcuts very effectively - simply place the offcuts on the bed of the laser and carefully position your designs using the Epilog Dashboard software. In Dashboard it is possible to "break apart" a design to split it over several pieces of material if needed.

On other machines such as the waterjet there are often part-used sheets of steel or aluminium in the material rack. Please use these before the