Troubleshooting (Haas ST-15Y): Difference between revisions

No edit summary |

No edit summary |

||

| Line 6: | Line 6: | ||

Drilling with one of the live tool spindles is usually a waste of time because the main spindle is much more powerful. Only use the live tool spindle if you need to drill off-axis. | Drilling with one of the live tool spindles is usually a waste of time because the main spindle is much more powerful. Only use the live tool spindle if you need to drill off-axis. | ||

== Workholding Problems == | |||

=== The program won't start because it says the spindle is unclamped, but it definitely is. === | |||

The workholding may have recently been changed. Check the value of Setting 282. | |||

When you are using the [[Klamp DKF65A6|collet chuck]] Setting 282 must be set to "OD". When you are using the [[Hydraulic 3-Jaw Chuck|hydraulic 3-jaw chuck]] it should be set to "ID". | |||

[[Category:CNC Machinery]] | [[Category:CNC Machinery]] | ||

[[Category:Fusion 360]] | [[Category:Fusion 360]] | ||

[[Category:Lathe]] | [[Category:Lathe]] | ||

Revision as of 18:40, 15 December 2023

Program/CAM Problems

When I start drilling a hole the live tooling motor turns on and the main spindle doesn't turn.

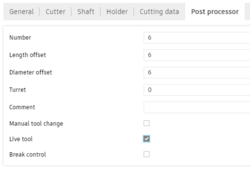

You have the "Live Tool" checkbox selected in the Post Processor tab of the tool you are trying to drill with. Uncheck this box to use the main spindle to drill with. Usually this happens if you are copying a drill bit from the mill tool library to use it on the lathe.

Drilling with one of the live tool spindles is usually a waste of time because the main spindle is much more powerful. Only use the live tool spindle if you need to drill off-axis.

Workholding Problems

The program won't start because it says the spindle is unclamped, but it definitely is.

The workholding may have recently been changed. Check the value of Setting 282.

When you are using the collet chuck Setting 282 must be set to "OD". When you are using the hydraulic 3-jaw chuck it should be set to "ID".